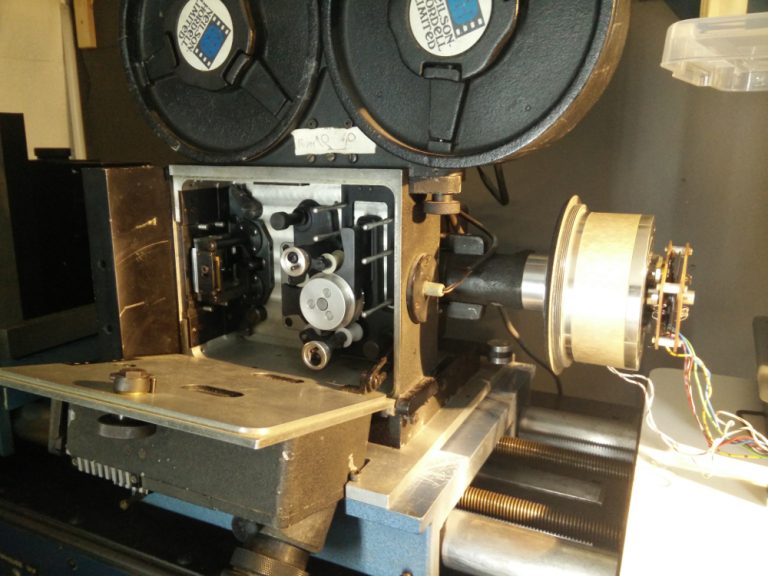

VERY great step forwards but I got the camera motor controller working and rigged it up to the camera to see how it runs and it runs smoothly, beautifully, accurately!!!.

The controller has loads of speeds that turn the main spindle/crank at different speeds so that means different exposure lengths AS WELL AS the different lengths provided by the variabe shutter which can be adjusted during running. The motor tacho EMF feedback circuit works well accurately registering the spindle/crank in precisely the same position each turn or run of turns. Next Ive got to design/build (probably Arduino) a gadget to measure the shutter speeds/exposure times and design a (better) system for programming sequences on the printer, remember the set-up as I was given it was configured for 1 to 1 blow up printing from S16m to 35mm/4 perf (full gate). This is a bit limited for me. I want to be able to run very complex mathematical ‘rhythms’ for want of a better term as well as obvious things like skip printing, reprinting, reverse printing, loop printing, etc.